Almost Everything You Need To Know About Gen-One Small-Block Chevy Engines

Article by Mark Trotta

Without a doubt, the most common V8 engine found in street rods and muscle cars is the small-block Chevy, and first-generation engines are the most preferred.

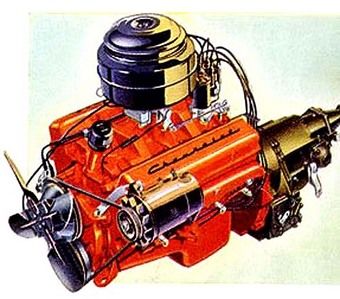

1966 327 small-block rebuilt by author

They are easy to repair, easy to upgrade, and availability of factory and aftermarket performance parts is second to none!

A Little History

Introduced in 1955, Chevy's small-block V8 was an instant hit with hot rodders. The first version had a 265 cubic-inch displacement, bored out to 283ci in 1957.

Read: Chevy Small-Block History 1955-1959

Read: Chevy Small-Block History 1960-1964

Early blocks had an oil filler tube in front of the intake manifold. There was no PCV system, instead, there was a draft tube in the lifter galley.

Read: Chevy Small-Block History 1965-1969

Up until the late sixties, small block valve covers had no holes for breather caps or PCV valves.

********************

327 Engine

In 1962, the 283 was bored and stroked to 327 cubic-inches. This was the first 4" bore small-block.

327 Chevy Articles:

327 Engine Build

Cylinder Head Assembly

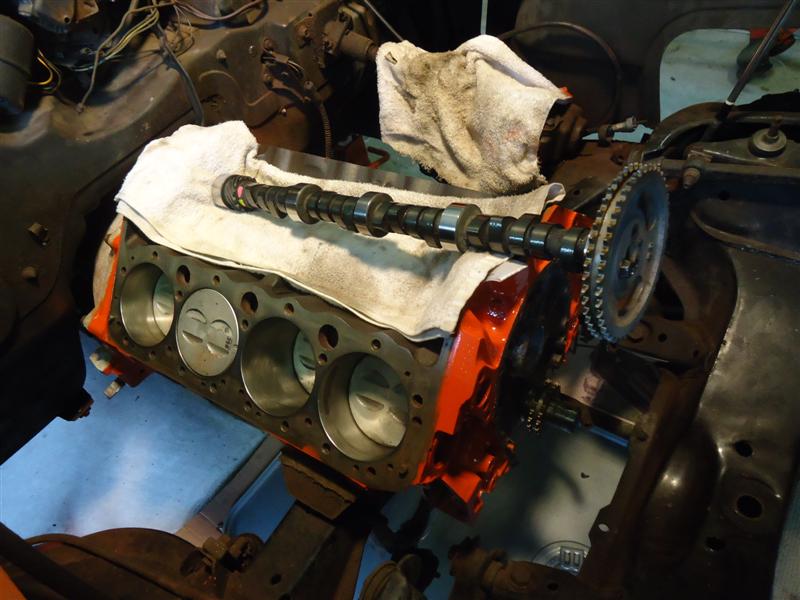

Camshaft Installation

Remove and Install Timing Chain

Valve Train Assembly

********************

Oil Filter Canister

Two types of canister filters were used on first-gen SBC's. Filter #PF131 is for 1956-1957 engines, and filter #PF141 is for 1958-1967 engines.

Through the years, many of these original canisters were taken off and replaced with the less-efficient but easier to replace spin-on oil filter. If your engine is missing one, replacement canisters are available.

Read: Old School Small-Block Chevy Build

Before installing the new filter and gasket, make sure you get the old gasket out! The seal is square and should come with the new cartridge filter.

Sometimes it's hard to tell if the old one is still up there. Shine a flashlight to check, and use a sharp awl or pick to stab it and pull it out.

*********************

350 Small-Block Chevy

An increase of piston stroke gave us the 350ci small-block in 1967. This displacement was the longest produced, and today, the most common.

Other first-generation engine sizes are 302, 400, 307, 287, 262, and 305.

Read: Does My Engine Need An Overhaul?

********************

Journal Size Increase

In 1968, the 327 Chevy small-block was updated with larger diameter crankshaft and connecting rod journals.

The main-journal size increased from 2.30" to 2.45". The rod-journal size increased from a 2.00" diameter to a 2.10" diameter, and the connecting rods were now heavier and used 3/8" diameter cap-bolts versus the smaller journal 11/32" diameter.

*******************

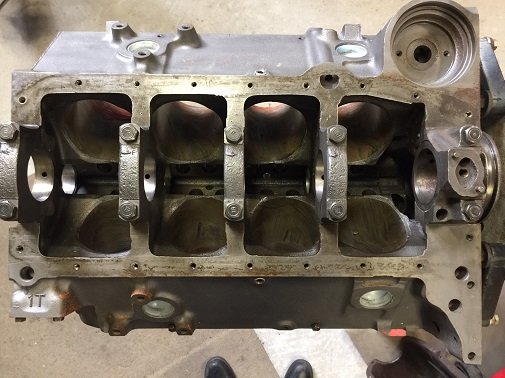

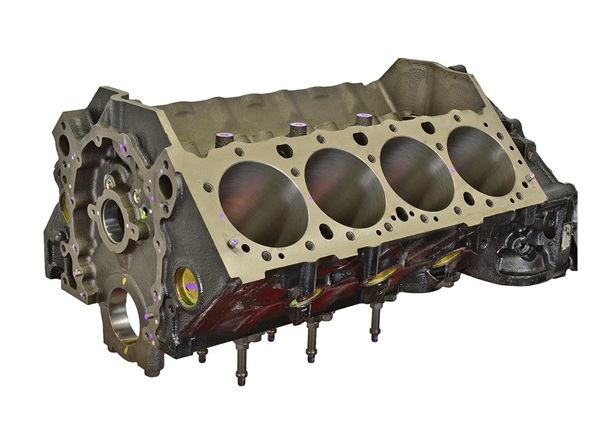

2-Bolt vs 4-Bolt Block

Chevy 350 blocks were produced with either 2-bolt or 4-bolt main bearing caps.

On 4-bolt blocks, the center-three main caps have two additional bolts, which were supported by the addition of heavier crankcase main-web bulkheads.

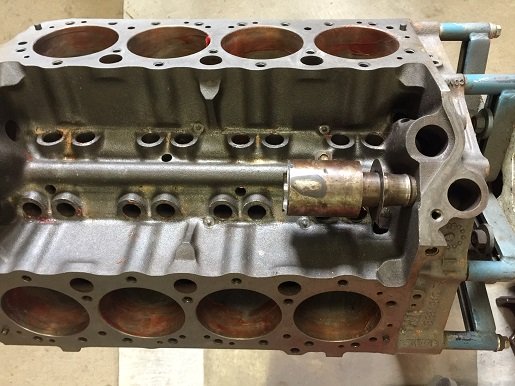

Pictured: 2-Bolt SBC Block

Several years back, there was a tech article where an engine builder tested a 2-bolt block to see how much power it would take before main cap flex. The horsepower level was near 600 before any main cap movement was detected.

So, if you're looking to build a healthy street motor, there's nothing wrong with a 2-bolt main block. But if your small-block Chevy build includes a high revving motor (over 6,000 rpm) and 500+ horsepower, a 4-bolt block is recommended.

********************

Was There A Factory 4-Bolt 327 ?

Although 283 or 327 Chevy blocks never left the factory with four-bolt main caps, they can and were added. Again, this is only required if your engine's making serious horsepower (500+) at very high revs (over 6,000 rpm).

Before doing this, consider selling your vintage block to a restorer and buying a newer 350ci crate motor.

********************

Gen-1 Cylinder Heads

Early small-block cylinder heads (pre-1970) did not have accessory mounting holes on the ends of the head. Except for some early truck applications, it was not until 1969 that all small-block cylinders had factory-equipped accessory holes.

Read: Best Heads For Gen-1 Small-Block Chevy

********************

Original LT-1 Chevy V8

The highest horsepower Gen-One small-block Chevy was the 1970 350 LT-1 motor. Factory-rated output was 370-horsepower in the Corvette, and 360-horsepower in the Camaro Z/28. The LT-1 featured a solid lifter cam, 11:1 compression, a 780cfm Holley four-barrel carburetor, and aluminum intake manifold.

Even today, 55 years later, engine builders will start with the specs of an first-Gen LT1 and then customize it to their personal requirements.

********************

SBC Camshaft Selection

In almost every SBC engine build, the camshaft is replaced along with the lifters.

Selecting a small-block Chevy cam usually involves a compromise between low-end and high-end power, but you don't need a wild camshaft to build a strong-running street V8.

********************

Hydraulic vs Mechanical Lifters

On first generation small-blocks, lifters were either hydraulic flat-tappet or solid flat-tappet, with hydraulic roller and solid roller designs available in the aftermarket.

Hydraulic flat-tappet lifters were most commonly used, having quiet operation and requiring no adjustment once installed correctly. They work well in both stock and modified engines to about 6,500 rpm.

Mechanical Lifters

Mechanical (solid flat-tappet) lifters are generally used in applications where very high RPM's (7,000 rpm or more) are needed. At idle, they will make a slight ticking sound, which is normal. They also need periodic adjustment.

One-Piece Rear Main Seal

In 1986, the two-piece rear main seal used since 1955 was replaced with a one-piece unit. Also this year, block displacement was now cast into the block next to the casting number.

********************

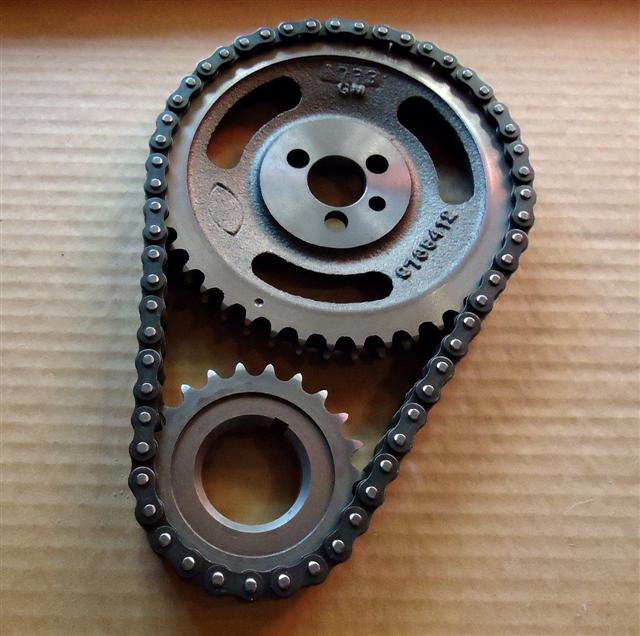

Timing Chain and Gears

Just like everything else for small-block Chevy engines, there's never-ending choices of timing chain and gear kits.

Read: SBC Timing Chain, Gears, and Cover

********************

Vortec Heads and Center-Bolt Valve Covers

Vortec heads were first offered on 1986 Corvettes, and were the first to have center-bolt valve covers.

During the 1986 production year, all-new aluminum heads brought a 40-pound weight savings and a five horsepower output improvement. Compression was boosted from 9.0:1 to 9.5:1, and they had better flow at lower lift than earlier heads.

To improve intake gasket sealing, the four mounting bolts were relocated into the valve cover center-line. This gave uniform sealing pressure on the cylinder head mating surface, virtually eliminating leakage problems.

Starting in 1987, all Chevy V8's were fitted with either cast iron or aluminum Vortec heads. Along with the new heads, factory roller cams with accompanying lifters and rockers were fitted to certain small-block engines.

Can I Put Vortec Heads On My Early Small Block?

Vortec heads will bolt up to earlier blocks, but they have taller intake ports than earlier heads. So, a later intake manifold needs to be fitted.

NOTE: There are adapters to put 'old school' perimeter-bolt valve covers on center-bolt heads.

********************

SBC Valvetrain

Small-block Chevy valve-train assembly includes lifters, push rods, rocker arms, rocker nuts, and rocker balls. All Gen 1 small blocks use the same valve timing procedure, but there are several sizes of balancers and timing pointers.

Read: SBC Valve Train Assembly

All Gen-1 SBC Chevy's use firing order: 1-8-4-3-6-5-7-2

********************

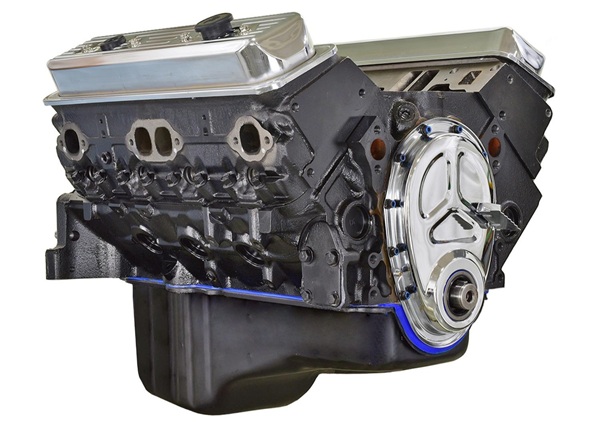

Current Production

Although not seen in a new car since 2003/2004, first-gen small blocks are still in production by a General Motors subsidiary in Mexico. They are sold under GM's crate engine program and still popular for replacement and racing/hot rodding.

If you're looking for more performance than stock, Summit Racing offers a wide variety of 350 Chevy Crate Engines.

Also available are brand-new bare blocks.

********************

Articles of Interest: