Remove and Install Gen-1 SBC Timing Chain

Article by Mark Trotta

Even though they're made of metal, automotive timing chains stretch and wear from mileage. When this happens, it effects engine timing, causing lost performance and hard starting.

On Gen-1 small block Chevy engines, replacing a timing chain is almost always done when replacing the cam and during an engine overhaul. If you're not sure how many miles are on yours, and you're considering replacing it, be prepared--there's a lot of steps involved.

*****************

The engine featured in this article is a 327 in a 1966 Corvette.

All Gen-One small-blocks will follow the same procedure.

*****************

Getting Started

If the engine is still in the vehicle, you'll need to remove the fan, shroud, radiator, and drive belts. With a pan or bucket underneath, drain engine coolant, then remove water pump.

Unbolt the bottom (crank) pulley from the harmonic balancer.

******************

Tools Needed

Along with basic hand tools, SBC timing chain replacement requires a harmonic balancer removal tool.

Back in the nineties, I bought a Cam Dynamics removal/installation kit, which was expensive even back then, but I got my moneys worth out of it.

Today, when you do a search for 'SBC harmonic balancer tool' it'll bring up tools for Gen III and Gen IV LS engines. If you're looking to buy one, looks like Lisle 45500 looks to be the best option.

Caution: When you attach the puller, make sure you have the correct thread bolts. They can be either 3/8" course or 3/8" fine thread. Also make sure that they thread in at least 3/8 of an inch.

Most small-block balancers have three bolts. This Corvette engine had a fourth (in the center).

NOTE: Very early small-blocks had just two bolt holes.

Loosen Oil Pan

On 1965 through 1986 small-blocks, the front of the oil pan needs to be dropped down about an inch to remove the timing chain cover. So if the motor is still in the car, that means getting underneath to loosen all the oil pan bolts.

NOTE: Unbolting the center link will give you more clearance.

Once the timing cover is off, rotate engine (with a socket on the crank bolt) until the timing mark on the crankshaft gear points straight down and the cam gear dot points straight up.

The three cam-gear bolts can now be removed. Carefully work the cam gear off it's dowel pin.

A gear puller is usually needed for the crank sprocket.

******************

Timing Chain Kit

For this engine, a Cloyes True Roller 9-3100 kit was selected. The double-roller chain features solid bushing rollers that really roll, and the pitch diameter is larger than stock, making it less prone to stretch.

The Cloyes cam sprocket is cast iron and dynamically balanced to 5,000 rpm. That equates to 10,000 rpm engine speed.

A double-roller timing chain with steel gears is really all you need for a street-driven car. For more SBC timing chain options click here.

******************

Timing Chain Installation

If installing a new cam, have the engine set on TDC (number 1 piston all the way up in bore).

Crank Gear

Check that there are no raised edges or burrs on the crank key. Lightly lubricate nose of crank with motor oil.

The crank gear may be installed in one of two ways. A suitably sized driver and mallet works best.

Alternatively, you can use a brass punch and tap around the gear until it seats.

Dot to Dot

To align the upper cam gear to the lower crank gear, each has a dimple, or a "dot" as a timing reference.

Rotate the crankshaft until the crank gear dot is at 12 o'clock. This sets the engine at Top Dead Center (TDC). If you have the heads off, the front drivers side piston will be all the way up in the bore.

On the cam gear, note the manufacturer's pre-marked timing dot, which should be at the 6 o'clock position when installing.

Wrap the timing chain around the cam gear, and then under the crank gear. Install cam gear, crank gear, and timing chain together.

With the dots lined up, push the cam gear on, then thread in bolts finger tight. Make sure the sprocket pulls up flush onto the camshaft.

Before going further, double-check that the crank gear and cam gear dots line up. With a socket and ratchet on the crank bolt, reverse the rotating assembly slightly and then forward, lining the dots up again, to make sure you're getting the most accurate reading.

For good measure, snap a picture of it.

Cam bolts torque to 30 pound/feet.

You can add a dab of non-hardening sealant to the three cam-bolts. This will insure the bolts remain torqued to the proper specification.

A camshaft bolt locking plate can also be added.

*****************

3-Keyway Crank Sprocket

There are three keyway slots in Cloyes crank sprockets. This gives you the choice of setting engine timing at either 4° advanced, 4° retarded, or factory standard.

For this installation, the factory setting was selected.

*****************

Timing Chain Cover

Before this 60 year-old timing chain cover was reinstalled, it was sanded down to bare metal, treated with phosphorous acid, then painted Chevy Orange.

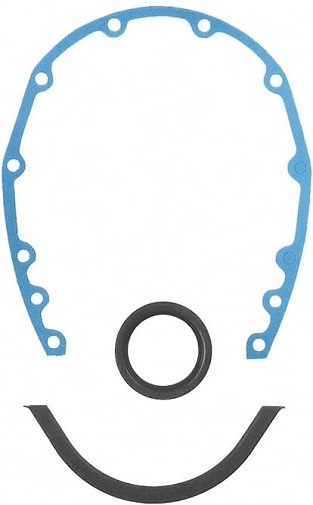

A new Felpro TCS45121 timing chain cover gasket was installed.

Timing chain cover bolts require just 7 to 9 lb/ft of torque.

*****************

Classic Car Engine Oil

The 10W-30 oil your car left the factory with is not the same 10W-30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters as well as the removal of ZDDP additives from motor oils.

Read: Best Oil for Classic Cars

*****************

Articles of Interest: