Gen 1 SBC Cylinder Head Assembly and Installation

Article by Mark Trotta

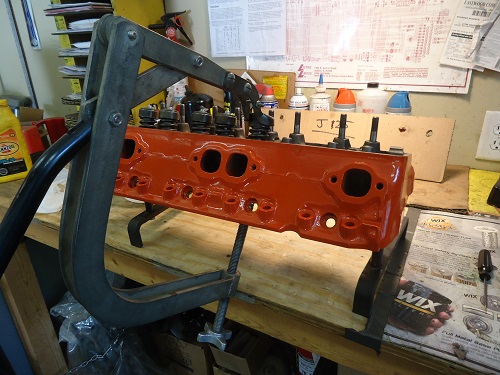

This 1966 327 Chevy small-block had been professionally rebuilt years ago but never fired up.

Regardless, a good mechanic assumes nothing.

The entire engine was disassembled and inspected, starting with the heads.

Remove Valves and Springs

After compressing the springs, the two small keepers can be removed with needle-nose pliers or a flat-blade screwdriver.

Releasing the tool (slowly!) releases the top retainer (also called a collar), metal shield, then the spring and valve.

TIP: It's a good idea to keep each valve, spring, retainer, and shield together.

Valve Spring Shims

If you have heads that were rebuilt before--and there's a good chance they were if they're Gen-One heads--there may be shims (spacer washer) underneath the springs.

After about 50k miles, Gen-1 valve springs begin to lose pressure. A shim may have been placed under some or all of the springs to compensate for the loss of strength.

Shims should not be used to increase pressure, as they may bind. And heavy-duty springs should be installed only if they're recommended for the cam you're using.

Oil Control

From the mid-fifties thru the mid-eighties, small-block Chevy's used an O-ring combined with the metal shield over the spring.

When the engine is fresh, this works very well, but as it ages, valve stem to guide clearance increases and allows oil consumption.

Some who don't understand this design will use the O-ring by itself, and discard the metal shield as unnecessary weight. This is not a good idea. The shield was intended to direct oil onto the valve spring and away from the stem. Taking away the shield renders the o-ring useless.

After disassembling, here's what was found--new guides, fresh seats, and new valves and springs.

Lapping the valves confirmed that the seats were airtight.

Only a cleaning and fresh paint was needed before reassembling.

Spray Paint Heads

The heads were cleaned with brake parts cleaner, wiped down with shop towels, then scuffed with a Scotch-brite pad.

To prevent over-spray, shop towels were balled up and stuck inside ports.

Instead of taping off the tops of the heads, a pair of old valve covers were temporarily installed.

A few coats of Chevy Orange Engine Paint was applied. No primer was needed.

Reassembly

Lightly lubricate stem with engine oil and install valve. They should be tight but move freely. If there's any binding, stop and find out why.

If you're using shims, install them now.

Install spring.

Install metal shield over spring.

Install retainer on top of the shield.

NOTE: Do not put O-ring on the valve before the metal shield. This will push the O-ring down the stem of the valve and do nothing to help oil control.

Compress spring with valve spring compressor until the top edge is visible, then install O-ring. Lubricate the O-ring with engine oil.

This Lisle 44300 valve spring compressor allows easy removal and installation of valves, locks, retainers, and springs.

Position two keepers in the groove above the retainer.

TIP: Coat the top of valve with wheel bearing grease. It holds the keepers in place.

Slowly release valve spring tool.

The keepers will either fall away or they'll hold!

Install Heads on Block

Before setting the heads back onto the block, cylinder head surfaces should be clean. Confirm that there are two dowel pins for each cylinder head to align onto.

NOTE: Felpro head gaskets are installed dry.

If you're re-using head bolts, clean them with a wire brush or wire wheel. Also, chasing the threads in the block is a good idea.

Re-use or Replace Head Bolts?

After cleaning and inspecting, these head bolts were deemed OK for re-use. If in doubt, replace.

Install Head Bolts

Some techs like to put a small dab of silicone sealer (like Permatex Ultra Black) on the bottom 1/4" of the head bolt threads, and a smaller dab of engine assembly lube underneath the head of the bolts. The sealant takes up the remainder of the space between the threads to prevent any leaks. Lubricating underneath the bolt-head gives more consistent torquing.

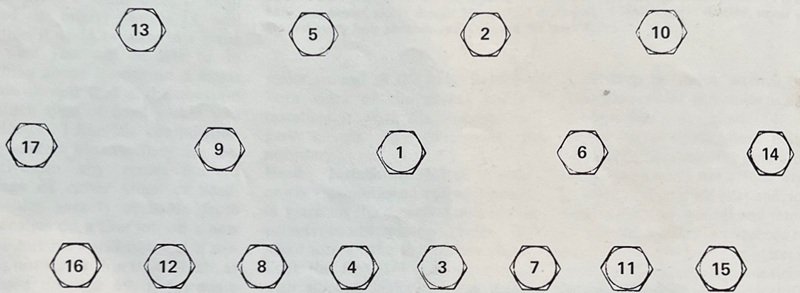

Head Bolt Torque Specs and Sequence

Head bolts should be torqued in the sequence shown below:

Snug bolts with a 3/8" ratchet. Start the torque sequence at 35, then go to 40, 50, 60, then 70 lb/ft.

Checking torque twice is good practice.

Read: Install and Adjust Rocker Arms and Pushrods

Notes and Misc

The only supplies needed included new valve stem seals, a little engine oil, valve grinding compound, and two small containers to keep parts in. Tools needed were a valve spring compressor and valve lapper.

**************

Related Articles: