Tools Needed For An Engine Build

Article by Mark Trotta

In addition to basic hand tools, automotive engine rebuilding requires a few specialty tools. Most of them are universal and will work on a wide variety of motors.

To date, the following tools have seen me through five classic car engine builds: three Gen-One Chevy small-blocks, and two Pontiac V8's

**********

Gasket Scraper

Aside from scraping surfaces clean before new gaskets are installed, gasket scrapers are also helpful when removing old gaskets.

They're also useful to help remove stuck oil pans, valve covers, and timing chain covers without damaging the thin sheet metal.

Piston Ring Expander

Piston ring expanders, also known as piston ring pliers, are very inexpensive tools.

Don't be tempted to install rings into the piston grooves by hand. Piston rings can get deformed by the twisting action, which may cause sealing problems.

Piston Ring Compressor

To install pistons and rings back into the cylinders, a piston ring installation tool is needed.

An automotive clamp-style ring compressor has a range of about 3" to 7".

Band-style ring compressors also work well.

Pictured: An assortment of six different band sizes.

**********

Torque Wrenches

A 1/2 drive torque wrench will get you through most engine overhauls.

Many mechanics, including myself, started out with a 1/2" drive, then added other sizes as the need arose.

Inch-Pounds

On torque values below 20 ft/lbs, values are listed as inch/pounds, and a smaller 3/8" drive is needed. These usually includes oil pan and timing cover bolts, which too many people (including yours truly) over-tighten!

Pictured: CDI 3/8 Inch Drive Torque Wrench has a range of 30-250 inch-pounds, so it goes up to 20.8 foot-pounds.

Example: timing chain cover bolts on Gen-One small-block's require just 9 lb/ft of torque, no more. It's not possible to do that with a 1/2" drive torque wrench.

Conversion: One foot-pound is equal to 12 inch-pounds, so 9 foot/pounds equals 108 inch/pounds.

Tap and Die Set

Going hand-in-hand with a torque wrench is a tap and die set. Why? Because you cannot correctly torque down bolts if threads are dirty - you'll get a false reading.

Related Article: Clean and Tap Bolt Threads

Aside from cleaning old threads, dies can also make new threads. With proper technique and lubricant, they will cut mild carbon, alloy steel, and cast iron. They also work on aluminum, brass, and bronze.

***********

Valve Spring Compressor

Depending on whether or not you're rebuilding cylinder heads yourself or farming them out, a valve spring compressor is needed for removing and installing the valves, springs, and keepers.

Pictured: Lisle 44300 valve spring compressor, made in USA.

Most valve spring compressors will work on a variety of cylinder head designs, so if other engine rebuilds are in your plans, it's a good investment.

Flex Shaft Rotary Tool

Electric rotary grinders are well-suited for automotive head work, such as porting, port matching, and removing casting flash.

Related Article: Best Tool For Cylinder Head Work

Valvetrain Organizer Tray

If you're rebuilding a V8, you've got 16 lifters, 16 pushrods, and 16 rocker arms. And if it's a Chevy, there's also 16 rocker balls and 16 locknuts. That's a lot of stuff to keep track of.

Pictured: Valvetrain Organizer Tray.

***********

Engine Measuring Tools

To rebuild an old engine, you first need to accurately inspect and measure the old, worn parts. You can pay a machine shop to measure cylinder bore wear and crankshaft and connecting rod journals, or you can invest in some precision measurement tools and do it yourself.

Measuring tools will include a digital caliper, micrometer(s), dial indicator, dial bore gauge, and feeler gauge. Not only is it important to have quality measuring equipment, you also need to learn how to use these tools correctly.

Dial Test Indicator (DTI)

Having a dial test indicator allows you to check end play, run-out, up-and-down movement, and many others.

Most have increments of .001" on a 0" to 1" scale. They can be mounted by clamp or magnetic base.

Engine clearances are crucial, and learning to correctly read precision instruments takes some time. Experienced mechanics always double-check their specs. First-time builders should measure a dozen times (or more) before trusting their readings.

Dial Bore Gauge

To accurately measure the inside diameter of a cylinder, a dial bore gauge is needed. The one in my garage has a range of two to six inches, a depth of six inches, and the round dial has .001" increments.

Dial vs Digital Caliper

Here's a link to a review of vernier, dial, and digital calipers, along with recommendations for digital calipers.

Remember that calipers, micrometers, dial indicators, and dial bore gauges are precision measurements, and need to be treated as such. For consistent and reliable results, keep them clean and out of harm's way.

For a full article on Measurement Tools For Engine Builders click here.

Feeler Gauge

A feeler gauge is used for checking valve tolerances, ignition point and ring end gaps, and other critical measurements.

Feeler gauges, also called gap gauges, are made up of many thin metal blades. Each blade is a different width of precise thickness, and will be marked in either thousandths of an inch, or millimeters, or both.

Certain engines will require long feeler gauges for valve adjustments.

***********

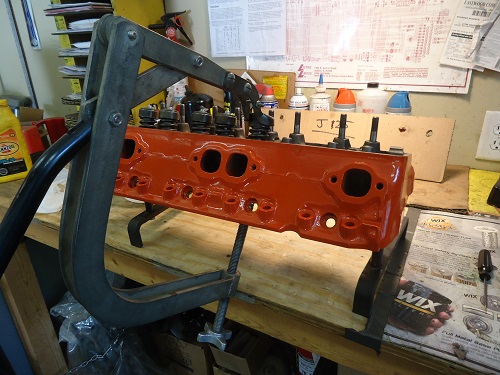

Engine Stand

Technically, you don't need an engine stand, but they sure do make things easier. The only provision here is to make sure it can safely handle the weight of your motor.

An engine stand must be two things: sturdy and stable. You can't have too heavy an engine stand.

Engine Hoist

Chances are you'll need an engine hoist twice; once to remove, and once to install. Inquire at a local auto parts store or an equipment rental store. Generally they offer two-day rentals, but you must leave a deposit, usually with a credit card.

I've done several motor pulls and have always rented one from a local auto parts store. I never considered buying a hoist, because even disassembled, they take up more space than I have to spare in my garage.

***********

Hand Tools Needed For Motor Overhaul

Sockets, ratchets, and extensions in 1/4", 3/8", and 1/2" drive

Shallow and deep sockets from 1/4" to 1"

Wrenches: open-end and combination, from 7/16" to 1"

Screwdriver set

Best Automotive Hand Tools

What Is A JIS Screwdriver?