Install and Adjust Gen 1 SBC Push Rods and Rocker Arms

Article by Mark Trotta

After cylinder heads are bolted on and torqued to specs, lifters, push rods, and rocker arms are next to be installed. All year and displacement Gen-1 small-blocks have the same valvetrain assembly procedure.

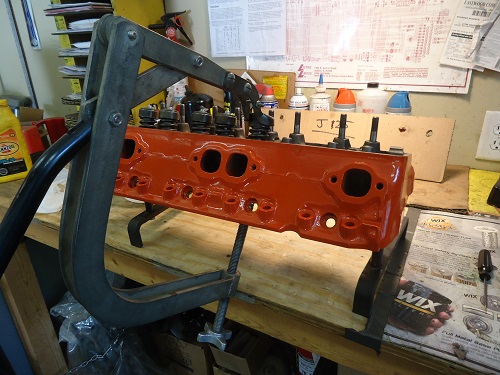

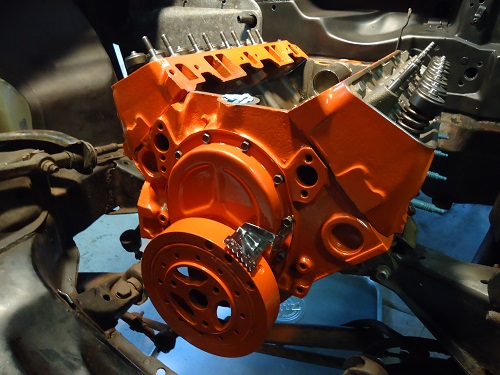

Pictured: Author's 327 Chevy Engine Build

********************

Install Lifters

If the lifters are new, they can go in any order in the block, but if you're re-using the old ones, they must be put back in the same bore they came out of. If not, they'll wear much quicker once the engine is running.

Use the same type of lubrication that you use on the cam lobes on the bottom of the lifters. Oil the sides of the lifters with motor oil. The lifters should drop right in.

Read: Best Engine Assembly Lube

********************

Install Push Rods and Rocker Arms

Just like old lifters, old push rods need to go back to the spot they ran in. Put a dab of assembly lube on each end before installing.

Having a valvetrain organizer tray will make assembly easier.

Push Rod Guide Plates

SBC guide-plate heads have large round holes as the plate keeps the push rod positioned.

On early small-blocks, a rectangular hole with semicircle is all that was used.

********************

On this motor, we're upgrading to grooved rocker balls, which hold additional lubrication for better protection against galling.

Before the rocker arms go back on, lubricate the side where the push rods sit, as well as the tips of the push rods and the tips of the valves.

Before you install them, lubricate the rocker balls, too.

Tighten the rocker nuts only finger-tight for now.

********************

Valve Adjustment

Adjusting valves with hydraulic lifters does not require shimming and is quite simple.

Hopefully, you left the engine on Top Dead Center before you installed the cylinder heads. If not, use a breaker bar and socket and turn the harmonic balancer so that the "0" mark lines up with the timing tab.

To check that you are on #1 cylinder, the lifters on #6 will be rocking (intake just opening and exhaust just closing). on its compression stroke (intake valve closing/exhaust opening for adjustment),

Adjust one cylinder at a time. With the engine at the TDC, tighten the rocker arm nut on cylinder #1 only until the slack between the rocker arm and push rod is gone. This is called zero lash (no push rod play).

Then tighten 1/2 turn to 1 full turn. This is called pre-load.

Next, turn the crankshaft nut 1/4 turn clockwise (facing the front of the motor) so the #5 cylinder lifters are rocking. This is TDC on cylinder #8.

Repeat the above procedure. Continue turning the balancer 1/4 at a time, and adjust cylinders 4, 3, 6, 5, 7, and 2. You will turn the balancer around twice and make four stops each pass (2 x 4 = 8 cylinders).

You will soon see a pattern emerge. Remember that first-gen SBC Chevy's use a firing order of 1-8-4-3-6-5-7-2, each cylinder gets adjusted when the valve-train is 180 degrees out. Example: cylinder 1 gets adjusted while 6 is rocking, cylinder 8 gets adjusted while 5 is rocking, etc.

Valve Adjustment Order for SBC

Adjust this cylinder - when lifters on this cylinder are rocking.

1 ------------ 6

8 ------------ 5

4 ------------ 7

3 ------------ 2

6 ------------ 1

5 ------------ 8

7 ------------ 4

2 ------------ 3

Hydraulic lifters contain a small hydraulic piston, which is pressurized by engine oil. The piston acts as a hydraulic spring that automatically adjusts the tappet clearance according to the oil pressure. This makes the valve actuation self-adjusting and there is no need to shim the rockers.

Be careful not to over-tighten, all you need to do is take the play out of the push rods, and the little hydraulic piston in the lifter takes up the rest.

After all 16 rocker arms are adjusted, bring the engine back to TDC (#6 lifters rocking again). This is where you need to be for the next step in engine reassembly--installing the distributor.

********************

Notes and Misc

On every engine build, parts go from static to running. This is why it's essential that during re-assembly, all parts are lubricated. This is necessary so that there will be no bare metal rubbing on metal during start-up.

Read: Best Engine Assembly Lube

Supplies included shop towels, engine assembly lube and a squirt can of motor oil.

********************

Related Articles:

327 Engine Build

327 Cylinder Head Assembly

Remove and Install Timing Chain

Tools Needed For An Engine Build

Old School Small-Block Chevy Build