389 Pontiac Engine Build

Article by Mark Trotta

Produced from 1959 to 1966, the Pontiac 389 V8 was offered in several high-performance packages, but certainly best known for it's Tripower option on GTO's from 1964 through 1966.

This article is an overview of the 389 motor build from my 1965 GTO.

With the motor out and secured onto the stand, engine overhaul began with cleaning and disassembly. This was followed by careful inspection and measuring of internal components.

Block and Cylinder Bores

Once the heads were off, it was found that the cylinder bores were a fresh .040" over, indicating a fairly recent rebuild. There were no ridges on the top of the cylinder walls, so all that was needed was honing and re-ringing the pistons.

**************

Engine bolts and bolt threads were cleaned and tapped.

This step is important, because dirty threads will give you false readings while final-torquing bolts.

**************

Crank and Rods

After inspecting the connecting rods for wear and ovality, the crankshaft was measured and showed .010" under stock on both the main and rod journals. Perhaps the old ones were reusable, but new bearings are fairly inexpensive.

While the crank and rods were at the machine shop being balanced, cylinder bores were honed with a flex-hone on a hand-held drill.

Rear-Main Rope Seal

Having previously rebuilt a 400ci motor from a 1969 Firebird, I was aware of the tricky two-piece rear-main rope seal.

Installing the rope seal so that it doesn't leak requires one side to be tucked slightly in, and the other side sticking slightly out of the cap. Same thing for the other half of rope seal in the other cap.

**************

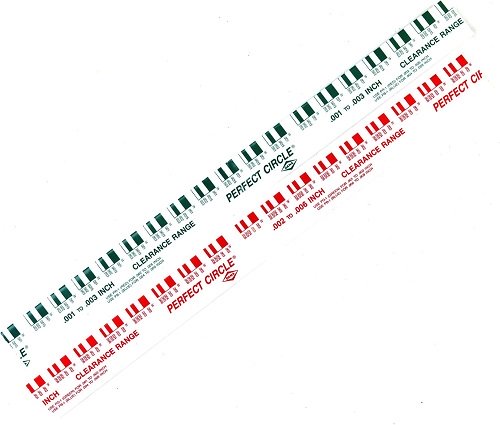

Is Plastigage Accurate?

For checking bearing clearances during engine assembly, Plastigauge is an accurate, inexpensive alternative to outside micrometers.

Green Plastigage Measures .001" to .003"

Red Plastigage Measures .002" to .006"

After the main bearings were checked for proper clearance, the bearings were lightly lubed and set into the block and main caps.

**************

Install Pistons and Rings

Piston rings were checked in their prospective bores before being installing on pistons. Top rings were gapped at .016" and the second rings at .013".

After the piston and rod assemblies were installed into the bores, rod bolts were torqued to 45 ft/lbs.

The crankshaft gets torqued to 100 lb/ft for the front four journals, and 120 lb/ft for the rear journal.

For the oil pump, a TRW #50049 high-pressure unit was selected.

**************

Tri-power Camshaft Choices

Two different camshafts were used for 1965 GTO engines. A 4-barrel carburetor motor had cam #9779067 (stamped "P"). Tri-power engines got #9779068 (stamped "S").

The 1966 Tri-power camshaft is #9785744 and is stamped "H".

For this '65 Tripower engine, the #9779068 cam was selected. This same cam was also fitted to 421 HO engines and several Ram-Air III applications.

Before installing, apply assembly lube to all cam lobes.

068 Cam Specs

Camshaft lift (at 1.50:1) is .407" intake and .447" exhaust. Duration at .050 lift is 288 degrees. Stock lifters will work fine up to 6,000 rpm. Recommended adjustment is .010" tighter than zero lash.

Timing Chain and Gears

After installing cam, a new Cloyes timing chain and gears were fitted. Install with the dots at 12 o'clock on the crank gear and at 6 o'clock for the cam gear.

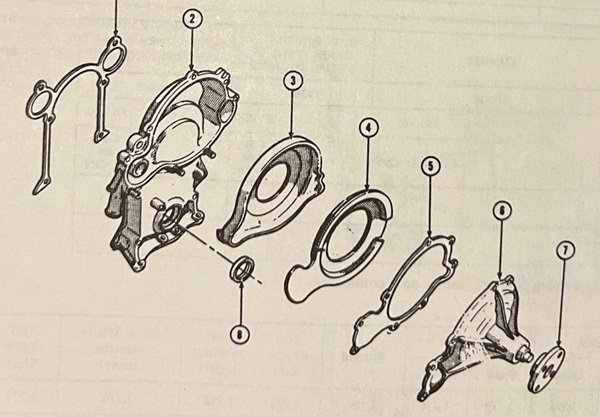

Timing Chain Cover and Water Pump Installation

Below is an exploded view of 1964-1968 Pontiac 389/400 water pump and timing chain cover.

Left to right: timing chain cover gasket, timing chain cover and seal, water pump housing, water pump divider, water pump to timing chain cover gasket, water pump and hub.

If you bought a full engine gasket set, everything was included. If not, you need a timing chain cover gasket set.

Mechanical Fuel Pump

To install the fuel pump, the arm has to be pressed against the fuel pump eccentric. An easy way to do this is by rotating the crank so that the eccentric is away from the arm. The eccentric is now all the way up, and the fuel pump should slide right in with almost no pressure.

**************

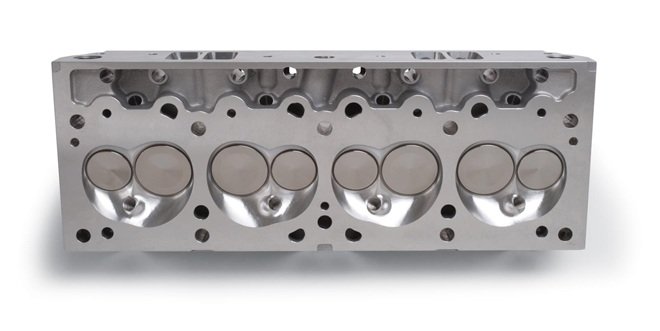

389 Cylinder Heads (1965/1966)

Correct heads for 1965 GTO Tripower engines are casting #77 and have 1.96" intake/1.66" exhaust valves. For 1966, most GTO models had a #093 head. California-bound GTO's in 1966 had different heads with an internal air galley.

Pontiac 400 Heads (1967)

When Pontiac increased engine displacement from 389 to 400 cubic-inches for 1967, the cylinder heads were redesigned and featured larger valves (2.11" intake and 1.77" exhaust). These were better breathing than earlier heads, and made more power.

Early vs Late Pontiac V8 Heads

All Pontiac V8 heads from 1967-up have a different valve angle from earlier heads, and require longer push rods and different rocker arms. 1967 and up valve covers were redesigned to clear the new valvetrain geometry (earlier valve covers won't fit).

In stock trim, the 1965 GTO 389ci Tri-power motor was rated at 360 horsepower. In a properly prepared car, that was good for 14-second quarter-mile times. But I wanted to have a little more power.

Pontiac 400 Heads On 389 Block

The 389 heads that came with the 1965 GTO were not in good shape, nor were they correct. After doing a little research, I found a pair of 1969 Ram-Air 3 heads (cast #16), which have larger valves and better breathing.

These are 400 heads, but will fit on a 389 block with no problems and will work fine, providing you use push rods, rocker arms, and valve covers for the 1967-up Pontiac 400 motor.

By using Ram-Air III heads on a 389 Tripower engine, the factory rating of 360 horsepower is significantly higher.

Pontiac Performer RPM Heads

The Edelbrock Performer series for Pontiac V8's was not around when this motor was built. But with the price of quality machine-work at an all-time high, these are definitely worth checking out.

Edelbrock 61599 heads feature 72cc chambers with 204cc intake runners, 2.11" intake and 1.66" exhaust valves, and have D-port exhaust. They are designed for use with hydraulic flat tappet camshafts.

Edelbrock 60599 heads feature 72cc chambers and 215cc intake runners, 2.11" intake and 1.66" exhaust valves. They have Ram Air IV round port style exhaust, which require specific exhaust manifolds or headers.

Either of these heads will bolt on to any 1959-1979 389, 421, 400, 428, or 455 block, but remember that pre-1965 cylinder heads and intake manifolds have different bolt patterns.

**************

389 Engine Torque Specs

Pontiac V8's have just ten head bolts, so correct torquing is critical. They are to be tightened to 90 lb/ft in 20 pound intervals.

On hydraulic cam Pontiac V8's, rocker arms are adjusted by tightening them to 20 lb/ft.

Intake manifold bolts get tightened to 40 lb/ft in 10 pound intervals.

**************

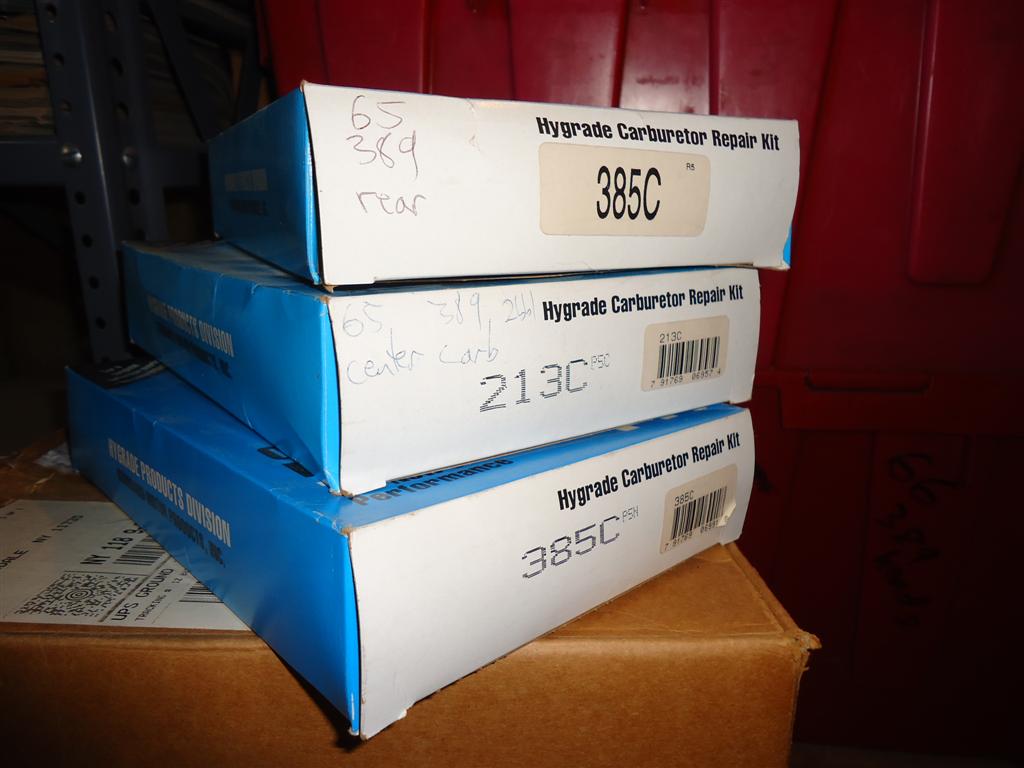

Tripower Carb Rebuild

When this car was purchased, the Tripower carbs were fairly intact, including the factory air-horn tags. The only factory parts missing were the steel fuel lines.

If you're missing fuel lines and fittings, don't be tempted to use rubber hoses and a chrome fuel block. On 1964/1965/1966 Tri-Power engines, there are potentially eight places for possible leaks (versus just two for a 4-barrel).

Rebuilding a Rochester two-barrel carburetor is pretty simple, especially compared to a 4-barrel Quadrajet carb. With a multi-carb set-up, keep one assembled to use as an example while rebuilding the other two.

Identifying Tri-power Carburetors

Rochester did not start stamping numbers on their two-barrel carburetors until 1968, and many people with earlier carbs mistakenly believe that the numbers which appear in a circle on the float bowl are carb numbers. These are actually casting numbers which Rochester used for many years on many different two-barrels, and will not help you determine if your two-barrel is a correct Tri-power carburetor or not.

All Tri-Power carburetors were identified by tag numbers attached to left-front air-horn screw, and these are more often than not missing. The best way to tell if it is a Pontiac Tri-Power carburetor is by the fuel inlet - center carbs have inlet facing forward, and outer carbs have outlet facing to the right.

Tri-Power Center Carburetor

The center carburetor supplies fuel to the engine by itself, until full throttle when the outer carbs kick in. Although the 1966 center carb has a larger throttle-bore (1-11/16") than the earlier carbs (1-7/16'), the venturi size is smaller. Center carbs of 1964 and 1965 Tri-Powers have 1-1/4" venturi. The 1966 center carb has a 1-3/16" venturi.

Tri-Power Outer Carbs

As mentioned, at part-throttle, the engine runs solely on the center carburetor, while the end carbs do nothing. At wide-open throttle, the linkage opens all six barrels. The outer carbs are very simple. They have no idle circuits and no choke. All outer carbs from 1959 to 1966 are similar, and have a 1-3/8" venturi.

Tri-power Carb Linkage

GTO's equipped with a 4-speed manual transmission used mechanical linkage, which work crisper than the vacuum-operated linkage found on automatic transmission models.

**************

Painting Cast-Iron

Applying a few coats of paint to a rebuilt engine provides protection as well as good looks. To get paint to properly adhere to a cast-iron, the metal must be clean and dry.

The motor was painted Pontiac "Robins Egg Blue" from a spray can.

Read: Spray Paint Engine

**************

Break-In Oil

Lucas 10631 SAE 30 is a high-zinc break-in oil used for flat tappet camshaft break-in. No moly supplement or additional additives are needed with this oil.

NOTE: Not recommended for passenger cars with catalytic-equipped emissions controls.

Classic Car Engine Oil

The 10W30 oil that your classic car left the factory with is not the same 10W30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters, as well as the removal of ZDDP additives from motor oils.

Read: Best Oil for Classic Cars

***************

Completion

After the carbs were rebuilt and reinstalled, the engine looked, sounded and ran great. The #068 cam gives a nice lumpy idle and all the torque you'd ever need for a street-driven car.

**************

Notes and Misc

When the modern Pontiac V8 was introduced in 1955, it displaced 287 cubic-inches. Over the next 15 years, displacement increased many times, (316, 347, 350, 370, 389, 421, 455), but external dimensions remained about the same.

Besides a variety of displacements, Pontiac V-8 blocks saw a number of minor changes over the years, including starter locations, main-journal diameters, engine-mounting points, and transmission bell-housing bolt patterns. Parts interchange between engines is good, but do your homework before swapping parts.

Fun Fact: Unlike Chevy small-blocks, on Pontiac V8's there is a 45° angle between the oil pan and timing cover which allows either to be removed without the other.

**************

Related Articles:

1965 GTO Restoration

Best Engine Assembly Lube

Best Oil for Classic Cars

Read: Dual Quad GTO

Auto Transport Information: Car Shipping | Calculate Auto Shipping