Camshaft Selection Small-Block Chevy

Article by Mark Trotta

Before computer-controlled engines, the 'brain' of the engine was the camshaft.

Camshaft selection dictates which engine components will work well together. Vehicle weight, engine compression, cylinder heads, valve size, transmission type, and other factors must all be considered.

Camshaft Basics

Camshaft basics start with the relationship between the rotation of the camshaft and the rotation of the crankshaft. This, along with the cam profile, determines the flow of the air/fuel mixture ratio.

The lobes on a camshaft push against the push rods and rocker arms to open the valves as the camshaft rotates. The valve springs push them closed on their return. In proper sequence, these series of events produce an efficient and strong-running engine.

Camshaft Lift

To a point, the further the valve rises from its seat the more airflow can be released. At very high RPM, valve bounce may result. This happens when valve spring tension is insufficient to keep the valve following the cam at its apex. Too high a lift may also cause interference with the valve head and the top of the piston.

If you can't decide between two cams, choose the milder one.

**********************

Camshaft Duration

Duration is the number of crankshaft degrees of engine rotation during which the valve is off it's seat. As you increase the duration of the cam, you increase the peak horsepower, but at the expense of low end torque. Do not to overdo the duration when selecting a camshaft. Over-camming is a common mistake when building a street motor.

Because different measuring points are used for advertised duration, the industry established .050" of tappet lift as a common measuring point, allowing cams from different companies could be accurately compared.

**********************

Single Pattern vs Dual Pattern

Camshafts were originally designed with the same duration and lift on both the intake and exhaust lobes. These are referred to as single-pattern cams.

Through the years, cam manufacturers have found that many engines prefer more duration on the exhaust lobe than on the intake lobe. These are called dual-pattern cams.

**********************

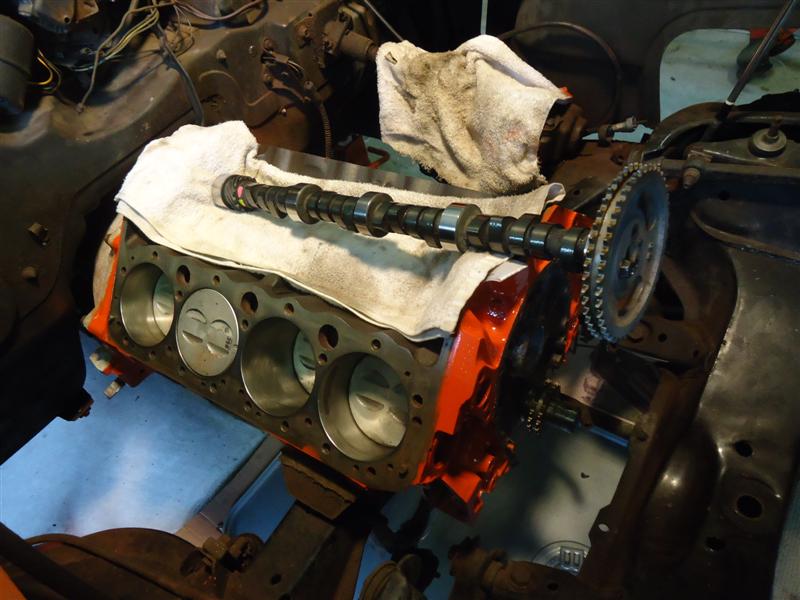

Edelbrock 2102 Camshaft Kit

This is one of Edelbrock's milder cams for 1957-1986 Chevy small-blocks. The 2102 cam will optimize low to mid-range torque, from off-idle to 5500 rpm. It features smooth idling for daily driven cars and light trucks.

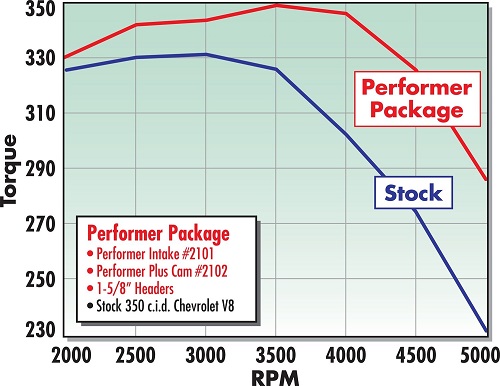

As you can see on the dyno chart results, there is a modest increase in throttle response and torque.

Edelbrock 2102 Cam Specs

- Advertised Intake Duration - 278 deg

- Advertised Exhaust Duration - 288 deg

- Intake duration: at .050 inch lift - 204 Degrees

- Exhaust Duration at .050 inch lift - 214 deg

- Intake Valve Lift - .420 in

- Exhaust Valve Lift - 0.442 in

- Lobe Separation - 112 deg

The cam kit includes camshaft, hydraulic lifters, assembly lube and instructions. The 2102 Edelbrock is to be used with stock ratio rocker arms only. Fits 1957-1986 small-block Chevy 283-400 V-8's and is 50-state legal.

Shop: Edelbrock 2102 Camshaft Kit

**********************

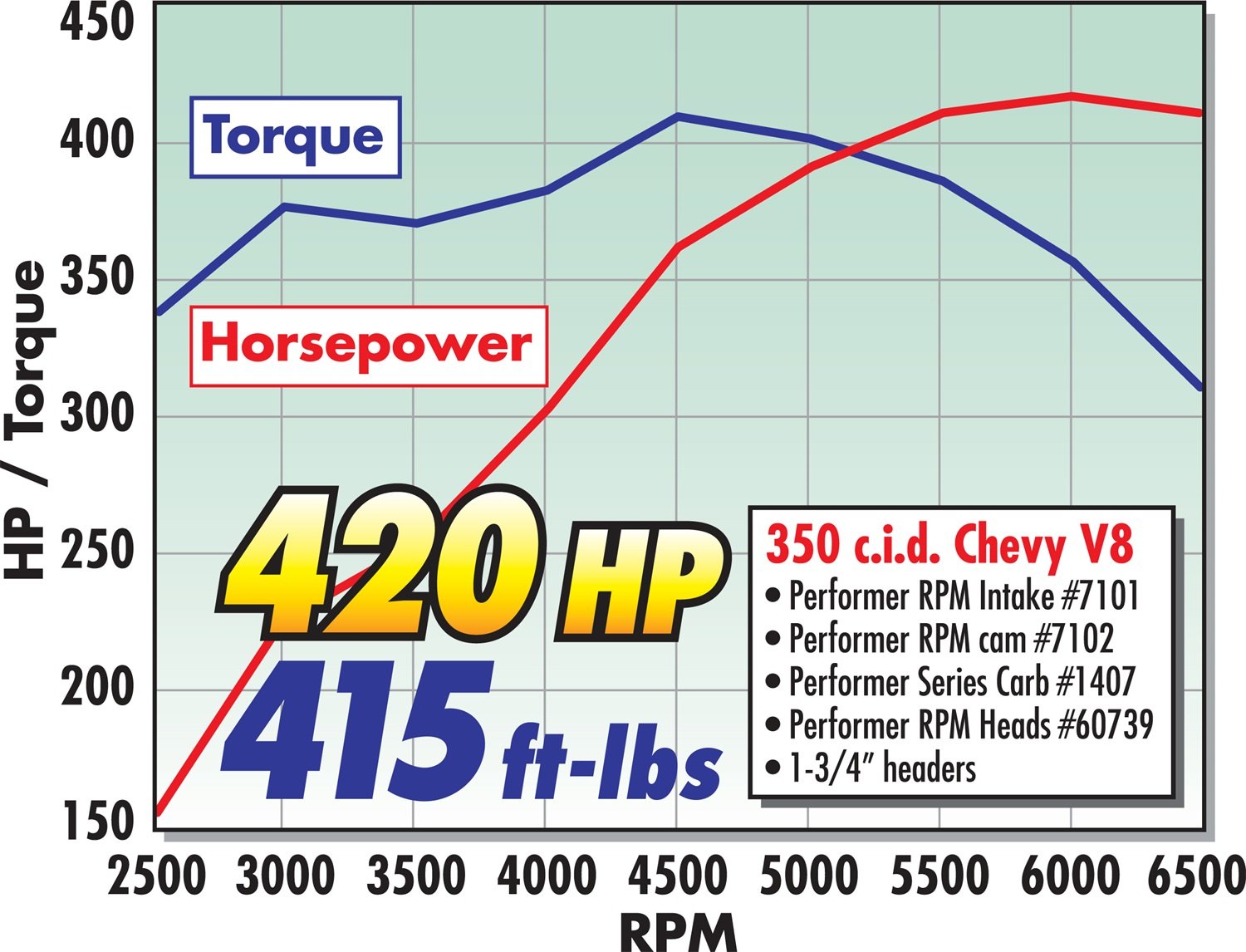

Edelbrock 7102 Camshaft Kit

From Edelbrock's "Performer Plus" series, the 7102 cam features a more aggressive profile than the 2102 cam. It is designed to increase horsepower and torque from idle to 6,500 rpm.

This is a good cam for high performance street use. It's also dyno-matched to Edelbrock's Performer line of intake manifolds.

Edelbrock 7102 Cam Specs

- Advertised Intake Duration - 308 deg

- Advertised Exhaust Duration - 318 deg

- Intake Duration .050 Inch lift - 234 deg

- Exhaust Duration at .050 inch lift - 244 deg

- Intake Valve Lift - 0.488 in

- Exhaust Valve Lift - 0.510 in

- Lobe Separation - 112 deg

Shop: Edelbrock 7102 Camshaft Kit

**********************

1970 Chevelle with SBC Camshaft Selection

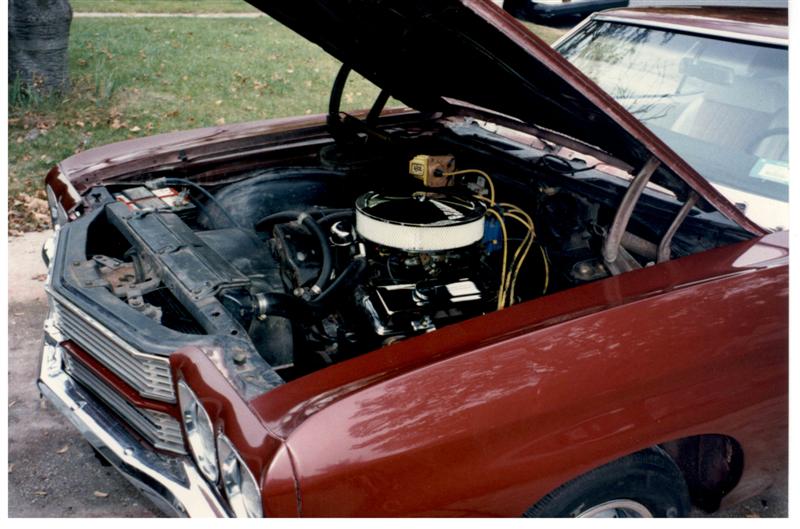

When I bought my old 1970 Chevelle, the engine had been modified with a slew of aftermarket pieces installed by the former owner. It made great power after 3,000 rpm, but was sluggish at lower RPMs.

Since the car was to used as a daily driver, I needed to bring performance back to a streetable level. I took out a 350 horsepower cam and installed a 300 horsepower cam, along with new timing chain and gears.

Also removed was a single-plane intake manifold and double-pumper carburetor, replaced with a dual-plane manifold and Holley 1850 carburetor.

These changes made the Chevelle a good daily driver, and still made enough power for occasional bursts of "spirited" driving.

**********************

Break-In Oil

Lucas 10631 SAE 30 is a high-zinc break-in oil used for flat tappet camshaft break-in. No moly supplement or additional additives are needed with this oil. Not recommended for passenger cars with catalytic-equipped emissions controls.

**********************

NHRA Stock Eliminator Winner

Back around 2010 or so, Wade Owens of Cape Girardeau, Missouri, ran a 283ci motor in a 1966 Chevelle, and successfully competed in NHRA's Stock Eliminator class. Duration on his cam was about 258/260 degrees at 0.050 inch, and lift for this engine combination was rules-limited to 0.399 inch, measured at the retainer.

With this relatively mild camshaft, Wade's Chevelle consistently ran in the mid-11s, which was at or under the national Stock Eliminator class record.

Read More about Wade here: Drag Central "Horsepower Happy"

**********************

Related Articles:

327 Chevy Camshaft Installation

SBC Timing Chain, Gears, and Cover

1966 Corvette Project

Best Engine Assembly Lube

The 10W-30 oil your car left the factory with is not the same 10W-30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters as well as the removal of ZDDP additives from motor oils.