327 Chevy Camshaft Installation

Article by Mark Trotta

Compared to other engines, the camshaft and lifters in small-block Chevy engines wear pretty fast, particularly if they're over-revved and don't get regular oil changes.

The engine featured in this article is a 300 horsepower 327 in a 1966 Corvette. The intake manifold is stock with a 4-barrel Rochester carburetor. The exhaust manifolds are factory ram horns.

***********************

The factory camshaft for this L75 motor has been long discontinued and homogenized into GM #3896929, which is similar. Several companies offer this cam, including Crane "Blueprint" series.

Read: SBC Camshaft Selection Guide

After a bit of research, a Melling MTC-1 cam kit was purchased. The kit came with American-made Johnson lifters, but new kits may not.

The following stats show how close this cam is to the original:

- Intake Valve Lift: OE cam .390" vs Melling cam .422"

- Exhaust Valve Lift: OE cam .410" vs Melling cam .444"

- Intake Duration at .050" Lift: OE cam 195 vs Melling cam 204

- Exhaust Duration at .050" Lift: OE cam 202 vs Melling cam 204

For 327 Camshaft Removal Click Here

***********************

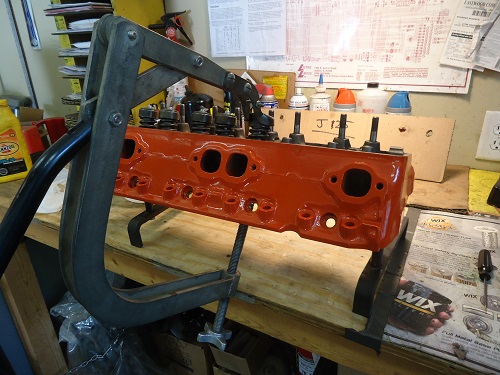

Cam Bearings

Before the new cam was installed, the bare block was taken to a local machine shop, and the old cam bearings (along with freeze plugs) were removed.

The block was then cleaned (hot-tanked), cylinders bored .030" over, and new cam bearings and freeze plugs installed.

***********************

Step-By-Step Camshaft Installation

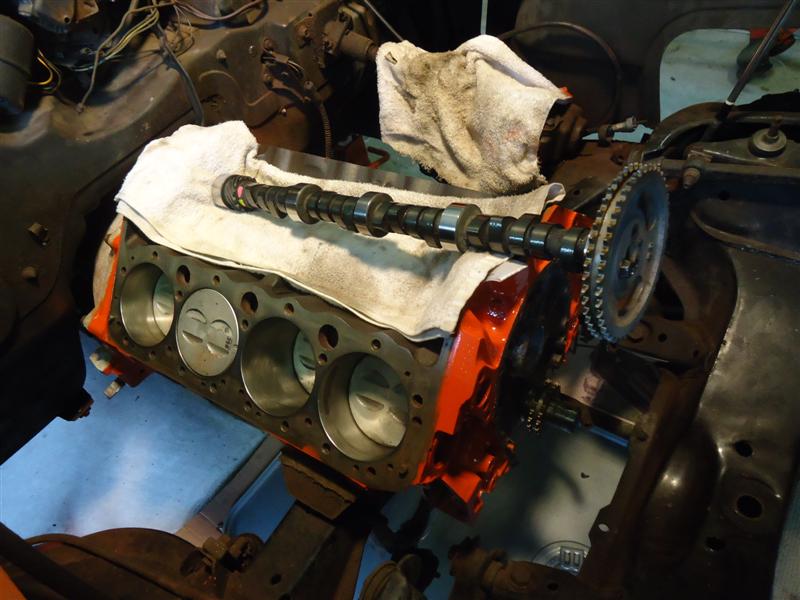

Clean and lube the new cam before installation. Most cam and lifter kits include assembly lube.

Coat the cam lobes, distributor gear, and fuel pump lobe completely, but not excessively.

The cam bearing journals were lubed with conventional SAE 30W oil.

The cam gear is temporarily installed with just one hand-tightened bolt. This allows us to use the cam gear as a "handle" and help guide the cam into the block.

Caution: Care must be taken not to nick the new cam bearings.

After the cam is in the block, remove the cam gear. The timing chain and two gears go on as an assembly.

Read: 327 Timing Chain Installation

***********************

Engine Break-In Oil

Lucas 10631 SAE 30 is a high-zinc break-in oil used for flat tappet camshaft break-in. No moly supplement or additional additives are needed with this oil. Not recommended for passenger cars with catalytic-equipped emissions controls.

Shop: High Zinc Break-In Oil

Classic Car Engine Oil

The 10W-30 oil your car left the factory with is not the same 10W-30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters as well as the removal of ZDDP additives from motor oils.

Read: Best Oil for Classic Cars

***********************

Articles of Interest:

SBC Camshaft Selection Guide

Best Engine Assembly Lube

Tools Needed For An Engine Build

327 Engine Disassembly

327 Bottom End