Repair An Old Floor Jack

Article and Pictures by Mark Trotta

Similar to brake calipers and wheel cylinders, rubber seals in a floor jack wear out over time and stops holding pressure.

Most old floor jacks can be rebuilt, provided a rebuild kit is available and no internal parts are damaged.

How They Work

While you're pumping the handle, fluid is getting compressed inside the cylinder. This "pressurizes" the hydraulic oil, producing adequate force necessary to lift a car or truck. When floor jacks get old, or have seen lots of service, the rubber seals and O-rings wear out and can no longer hold pressure.

Check Fluid Level

Before assuming it needs a rebuild, look for any external oil leaks around the pump. Check if the fluid is low.

The port where fluid goes in (and comes out) is often hard to find. It's located in different places on different brands.

The port on this old jack was hidden under a cover.

Although my jack was dry on the outside, it was pretty low on fluid. I filled it up and bled the system, but it still wouldn't hold pressure.

NOTE: Only use hydraulic jack oil in hydraulic jacks.

Try Bleeding The System

Sometimes air bubbles get trapped in the system, which may prevent it from holding full pressure. To purge the jack of air bubbles, open the release valve fully (turn handle CCW), then work the jack handle up and down several times while leaving the valve open.

If your floor jack has no external leakage, and filling it with oil and purging the air doesn't solve the problem, the seals in the pump need replacing.

**********************

Repair Or Replace Floor Jack?

Although I had never rebuilt a floor jack before, I decided to try it. The way I figured it was, if I tried to rebuild it and failed, at the very most, I've wasted a few hours and the cost of the rebuild kit. And I could sell it for scrap metal now that it's disassembled (most scrap dealers won't accept assembled jacks).

**********************

Parts Kit Availability

Before you start, see if a repair kit is available. Sometimes it's hard to tell the make and model because it's so old and worn.

Seal kits are readily available for major brands like Craftsman, Lincoln, Walker, and Hein-Werner. If yours is an overseas unit, a seal kit may be harder to find.

Shop: Floor Jack Repair Kit

My floor jack is an ATD model 7300, made in Brazil, and rated at 2-1/4 tons.

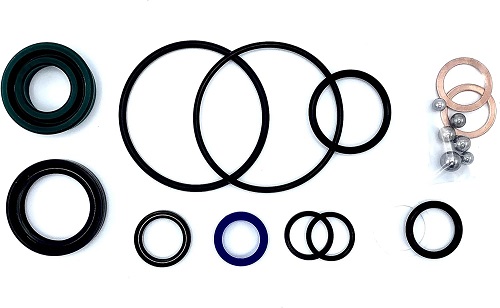

Repair kits generally include all O-rings and seals needed. After ordering the repair kit, I sprayed the jack with WD40 and began disassembly.

**********************

Tools Needed

Pictured are most of the tools needed to repair my old floor jack. Pulling out the old seals was done with a 90 degree "picker-outer" tool (not shown).

Minimum workbench space required is two feet by four feet.

During disassembly, I kept the parts separate and put them in marked sandwich bags. This made reassembly much easier.

Jack Disassembly

Procedures for removing the jack from the frame will vary. On mine, it involved the following:

Remove Handle

Two flat-blade screws held the handle on.

Remove Drift Pin From Pump Beam

I started with a drift pin punch, but the pin started to distort and got stuck. Fortunately, I was able to grab it from the other side with a pair of pliers and pull it through.

Remove Pump Axle From Frame

After removing an E-clip from one side, I knocked the axle out through the other side.

Remove Springs (long pair)

I thought the long springs would be under heavy tension but they weren't.

Remove Springs (short pair)

The two short springs can be removed after the jack is removed from the frame.

Once the jack was out of the frame, I turned it over and drained the old fluid into a plastic container.

**********************

Pump Disassembly

On the top of the pump is a big shouldered nut, called the head nut, which the lift piston slides in and out of. I didn't have a wrench that big, so I used a large monkey wrench.

Once completely loosened, the head nut came off with the lift piston attached to it. Sometimes getting them apart is a hassle, but in my case, the piston came out with little resistance.

Notice if the old fluid is foamy or milky. That's a sign of moisture in the system, which corrodes metal.

There were two seals in the head nut. One was about 3" x 1/8" that sealed the top of the canister, and the other was about 2" x 3/8".

I scuffed the lift piston with fine Emory cloth and steel wool to remove several small scratches.

The (blue) seal on the end of the lift piston was 1/8" thinner than the old seal, which was swollen from age.

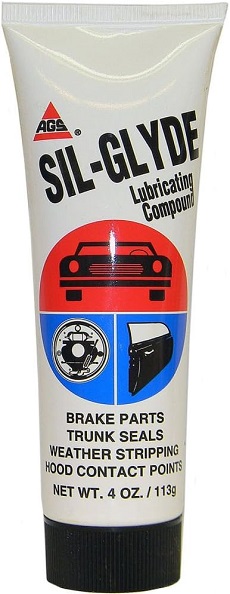

AGS Sil Glyde is a good lube to use when re-installing hydraulic jack parts.

**********************

Floor Jack Illustrations

Lazzar's Floor Jack Supplies has illustrations of different brands and models of floor jacks on their website, which can be downloaded for free.

**********************

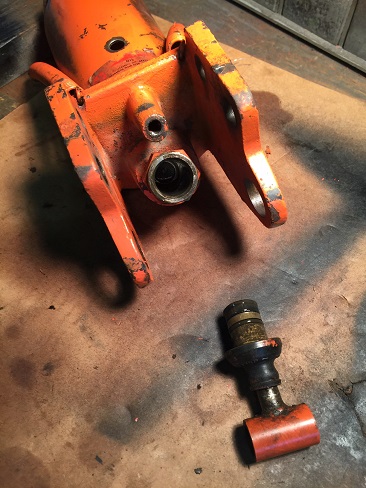

At the bottom of the pump is the pump piston, which is activated by the floor jack handle.

The pump piston has two seals which get replaced.

I was disappointed that a new dust boot was not included in the $40 repair kit. I ended up re-using the old ripped boot.

Unscrewing the small cylinder from the pump reveals an O-ring, metal washer, screen, and a small ball bearing, which acts as a check valve.

The screen acts as an oil filter. Make sure the ball bearing is in place before you put back the screen and washer. The new O-ring can now be installed.

All parts were cleaned with brake parts cleaner and blown dry with compressed air before reassembling.

**********************

The first time I reassembled the pump and filled with jack oil, it began leaking. So I took it back apart, saw where the leak was coming from (the 3" o-ring on the bottom), then carefully reassembled.

Getting the hydraulic pump back into the frame required a little strategy and a little muscle.

To test that the jack would hold weight under pressure, I took it out to the driveway and placed it under my truck. I lifted it up until one wheel came off the ground, then let it sit for a few minutes.

Only use hydraulic jack oil in hydraulic jacks.

Before installing the new O-rings and seals, coat them in hydraulic oil.

Jack oil can be recycled with used motor oil.

Never crawl under a car that is supported only by a floor jack.

Always use jack stands when underneath a car.

Always release pressure on a hydraulic jack before storing it.

**********************

Replacement Floor Jack Casters

If your floor jack's wheels are cracked or broken you can buy replacement casters here.

**********************

Conclusion

Unless you repair hydraulic pumps for a living, rebuilding an old floor jack will likely be a long and tedious task. If you can't or don't want to repair yours, buying a new floor jack is the best solution.

**********************

Update

After five years of occasional use since the overhaul, the floor jack lost pressure again, and I was just starting to do a brake job on the driveway, with one side of the vehicle already jacked up. I went around to do the other side, and no matter how many times I pumped it, the jack wouldn't go up an inch.

So now I'm stuck with my wife's SUV lifted up on one jack stand. I hopped into my truck, drove to a local NAPA store, and bought an Evercraft 2-1/4 ton unit.

For safety's sake, I'm not rebuilding a 25 year old floor jack twice.

**********************