Rebuilding 327 Heads

Article by Mark Trotta

Gen-One small-block Chevys are known for faster-than-usual valve-guide wear, so it's essential to measure the valves and guides when rebuilding 327 heads. If measurements prove to be out of tolerance, replacing the guides is recommended.

Specialty Tools

Tools needed for cylinder head rebuilding include a valve spring compressor, thread chaser, gasket scraper, and caliper or micrometer.

Supplies include engine oil, new seals, and a few small containers for parts.

____________________________________________

____________________________________________

Once the heads are off the engine, a valve spring compressor is needed for removal of valves, locks, retainers, and springs. They are hand-operated with an extendable arm.

Most valve spring compressors will work on a variety of cylinder head designs, so if other engine rebuilds are in your plans, it's a good investment.

Remove Valves and Springs

After compressing the springs with the valve-spring compressor tool, carefully remove the two small keepers with either a small flat-blade or needle-nose pliers.

Release the valve spring compressor slowly, then remove the metal shield and valve spring. If the head has been rebuilt before, there may be a shim underneath the spring. Make a note of where and how many shims there are.

Remove the O-ring from the groove and slide the valve out. It's a good idea to keep each valve, spring, and shield together.

From the factory, stock cast-iron Chevy heads were fitted with cast-iron valve-guides, which were made by boring a hole through a boss cast into the head. Refinishing the guide is done either by knurling, or pressing in a new guide of iron or bronze alloy.

If measurements are found to be within tolerance after disassembly, all that's required is a thorough cleaning and reassembly.

The machine work on these 327 heads was fresh. The valves and seats were cut and the valve guides were knurled. Regardless, I still checked valve to guide clearance. I measured both top and bottom of the valves with a micrometer.

____________________________________________

____________________________________________

The knurling process is done by passing a tool down the guide, which rolls a spiral of material into the spaces of the tool. The guide is then refinished with a reamer to proper size for the valve stem to be used.

Another method for checking guide wear is to hang the valve out the guide just an inch or so (with the head laying sideways), then rocking the valve side to side.

Oil Control

From the mid-fifties thru the mid-eighties, small-block Chevy's used an O-ring combined with the metal shield over the spring. When the engine is fresh, this works very well, but as it ages the stem to guide clearance increases and allows oil consumption. GM used this design until emission concerns came along.

Some who don't understand this design will use the O-ring, but discard the metal shield as unnecessary weight. The shield was intended to direct oil onto the valve spring and away from the stem. Taking away the shield renders the o-ring useless.

Note: when reinstalling, do not put the O-ring on the valve before the metal shield. This will push the O-ring down the stem of the valve and do nothing to help oil control.

Valve Springs

After 50k miles, SBC valve-springs often begin to lose pressure. If yours are worn slightly, a spacer washer (shim) can be placed under the spring to compensate for the loss of strength.

____________________________________________

____________________________________________

Shims should never be used to increase pressure, as they may bind. Heavy-duty springs should be used only if recommended for the cam you're using.

After lapping the valves, I found they were airtight.

Paint Cylinder Heads

I cleaned and scuffed the heads, then sprayed them with brake parts cleaner (leaves no residue) and wiped them down with shop towels.

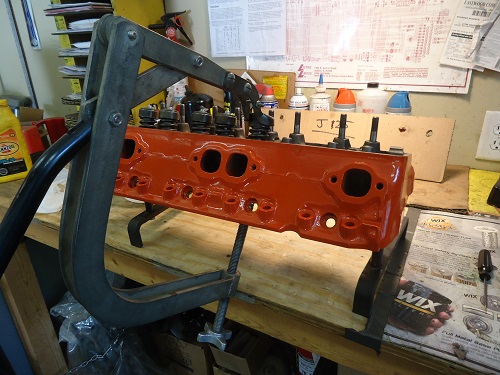

After taping them up, I sprayed them with a few coats of Chevy Orange Engine Paint. No primer is needed.

That's an old set of old valve covers I installed while painting.

Read: Spray Paint Engine Block And Parts

Clean both cylinder head surfaces before setting the heads back onto the engine. The block should have two dowel pins for each cylinder head to align onto.

Re-use or Replace Head Bolts

Although the head bolts on this Chevy 327 are over 50 years-old, they were OK to re-use. I can't think of the last time I heard of a SBC head bolt failure.

Thoroughly clean all head-bolt threads before re-installing. I cleaned mine on a wire wheel. Also, chasing the threads in the block is a good idea.

____________________________________________

____________________________________________

Some techs like to put a small dab of Permatex Ultra Black on all head bolt threads (on the bottom 1/4"), and a smaller dab of engine assembly lube underneath the top bolt-heads. The sealant takes up the remainder of the space between the threads to prevent any leaks. Lubricating underneath the bolt-head gives more consistent torquing.

Felpro head gaskets are installed dry.

Last step is to torque the bolts in steps. First, Hand-tighten them with a 3/8" ratchet, then torque to 40, 50, 60, and then 65.

****************************

Related Articles:

Best Engine Assembly Lube

327 Chevy Build

Best Digital Caliper For Engine Building

SBC Timing Chain, Gears, and Cover

Tools Needed For An Engine Build

The 10W-30 oil your car left the factory with is not the same 10W-30 that you buy today. There are more flat-tappet hydraulic cam failures than ever before, brought about by inferior foreign lifters as well as the removal of ZDDP additives from motor oils.